Stainless steel 904L

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Product introduction

904L stainless steel is a non-stabilized austenitic stainless steel with low carbon content. This high alloy stainless steel is added with copper to improve its resistance to strong reducing acids, such as sulphuric acid. The steel is also resistant to stress corrosion cracking and crevice corrosion. 904L is non-magnetic, and offers excellent formability, toughness and weldability.

904L contains high amounts of expensive ingredients, such as molybdenum and nickel. Today, most of the applications that employ grade 904L are replaced by low-cost duplex stainless steel 2205.

| ITEM | Stainless Steel Sheet From China Facotry |

| Grade |

201.202.301.302.304.304L.310S.316.316L.321.430.430A.309S.2205.2507.2520.430.630.631 .410.440.904Lect. Or Customized |

| Certificate |

SGS,BV,IQI,TUV,ISO,etc |

| Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

| Standard | GB, AISI, ASTM, ASME, EN, BS, DIN, JIS |

| Package | Standard export sea-worthy packing or customized |

| MOQ | 1Ton |

Technical data

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu | |

| 904L | min. max. |

- 0.02 |

- 2 |

- 1 |

- 0.045 |

- 0.035 |

19 23 |

4 5 |

23 28 |

1 2 |

Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) | Brinell (HB) | ||||

| 904L | 490 | 220 | 36 | 70-90 typical | 150 |

Physical Properties

| Grade | Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Elec Resistivity (nΩ.m) |

|||

| 0-100°C | 0-315°C | 0-538°C | At 20°C | At 500°C | |||||

| 904L | 7900 | 190 | 15 | - | - | 11.5 | - | 500 | 952 |

Grade Specification Comparison

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 904L | N08904 | 904S13 | - | 1.4539 | X1NiCrMoCuN25-20-5 | 2562 | - |

Possible Alternative Grades

| Grade | Reasons for choosing grade 904L |

| 316L | A lower cost alternative, but with much lower corrosion resistance. |

| 6Mo | A higher resistance to pitting and crevice corrosion is needed. |

| 2205 | A very similar corrosion resistance, with the 2205 having higher mechanical strength, and at a lower cost to 904L. (2205 not suitable for temperatures above 300°C.) |

| Super duplex | Higher corrosion resistance is needed, together with a higher strength than 904L. |

Stainless Steel Seamless Pipe

Item |

Standard | ASTM A213/A213M | ASTM A312/A312M | JIS G 3459 | |||||||

| Grade | TP304 TP316 TP317 TP347 TP309H* |

TP304L TP316L TP317L TP310S TP310H* TP321H△ |

TP304 TP316 TP317 TP317 TP317* |

TP304L TP316L TP317L TP310S TP310H* TP321H△ |

SUS 304TB SUS 316TB SUS 317TB SUS 310TB SUS 321TB SUS 321HTB* |

SUS 304LTB SUS 316LTB SUS 317LTB SUS 310LTB SUS 347TB |

|||||

| Yield Strength | ≥170; ≥205 | ≥170; ≥205 | ≥170; ≥205 | ||||||||

| Tensile Strength | ≥485; ≥515 | ≥485; ≥515 | ≥485; ≥520 | ||||||||

| Elongation | ≥35 | ≥35 | ≥30; ≥35 | ||||||||

| Flattening test(mm) | H=1.09t/(0.09+t/D)and test completeness | H=1.09t/(0.09+t/D)and test completeness | H=1.09t/(0.09+t/D) | ||||||||

| Expanding test(mm) | Expanding rate of inside diameter is21-68% | α=60° Expanding12%D | |||||||||

| Grain size | "*""△"ASTM E112"△"No.7or thicker | "*""△"ASTM E112"△"No.7or thicker | “*”、JIS G0551 7# or 7#above | ||||||||

| Hydraulic test(MPa) | D | Pmax | Hydraulic test p=220.6t/D designated by user and can be replaced by nondestructive flaw detection |

D | Pmax | ASTM A530 /A530M D≤270mm P=2Rt/D in the formula R=50%σ0.2 |

P=2Rt/D in the formula R=0.6σ s can be replaced by nonderstructive flaw detection |

||||

| <25.4 | 7 | ||||||||||

| 25.4-<38.1 | 10 | ≤88.9 | 17 | ||||||||

| 38.1-<50.8 | 14 | ||||||||||

| 50.8-<76.2 | 17 | >88.9 | 19 | ||||||||

| 76.2-<127 | 24 | ||||||||||

| ≥127 | 31 | ||||||||||

| Ntergranular corrosion test | ASTM A262 E method (supplemental requirement) | ASTM A262 E method (supplemental requirement) | JIS G0575(special requirement) | ||||||||

| Nondestructive flaw detection |

ASTM E213 E309 E426 | ASTM E213 E309 E426 | Can use eddy current or ultrasonic flaw detection eddy current JIS G0583EV ultrasonic JIS G0582 UD | ||||||||

| Heat treatment | Requirements | Requirements | Requirements | ||||||||

| Permitted variations in outside diameter (mm) |

Outside diameter | Permitted variations in outside diameter |

Outside diameter | Permitted variations | Outside diameter | Permitted variations | |||||

| <25.4 | ±0.10 | 10.3-48.3 | +0.40/-0.80 | <30 | ±0.3 | ||||||

| 25.4-≤38.1 | ±0.15 | >48.3-114.3 | +0.80/-0.80 | ||||||||

| >38.1-<50.8 | ±0.20 | >114.3-219.1 | +1.60/-0.80 | ||||||||

| 50.8-<63.5 | ±0.25 | >219.1-457.2 | +2.40/-0.80 | ≥30 | ±1% | ||||||

| 63.5-<76.2 | ±0.30 | >457.2-660.4 | +3.20/-0.80 | ||||||||

| 76.2-≤101.6 | ±0.38 | >660.4-864 | +4.00/-0.80 | ||||||||

| >101.6-≤190.5 | +0.38/-0.64 | >864-1219.2 | +4.80/-0.80 | ||||||||

| Permitted variations in wall thickness |

>190.5-≤228.6 | +0.38/-1.14 | Permitted variations in wall thickness(mm) ±12.5%t |

t<2 | ±0.2 | ||||||

| Outside diameter | Permitted variations in wall thickness |

||||||||||

| ≤38.1 | +20%t/-0 | t≥2 | ±10% | ||||||||

| >38.1 | +22%t/-0 | ||||||||||

| Bending | Reasonable straightness | Reasonable straightness | Practical straightness | ||||||||

| Other requirements | HRB<90 | HRB<90 | Hardness HRB<90(special requirement) | ||||||||

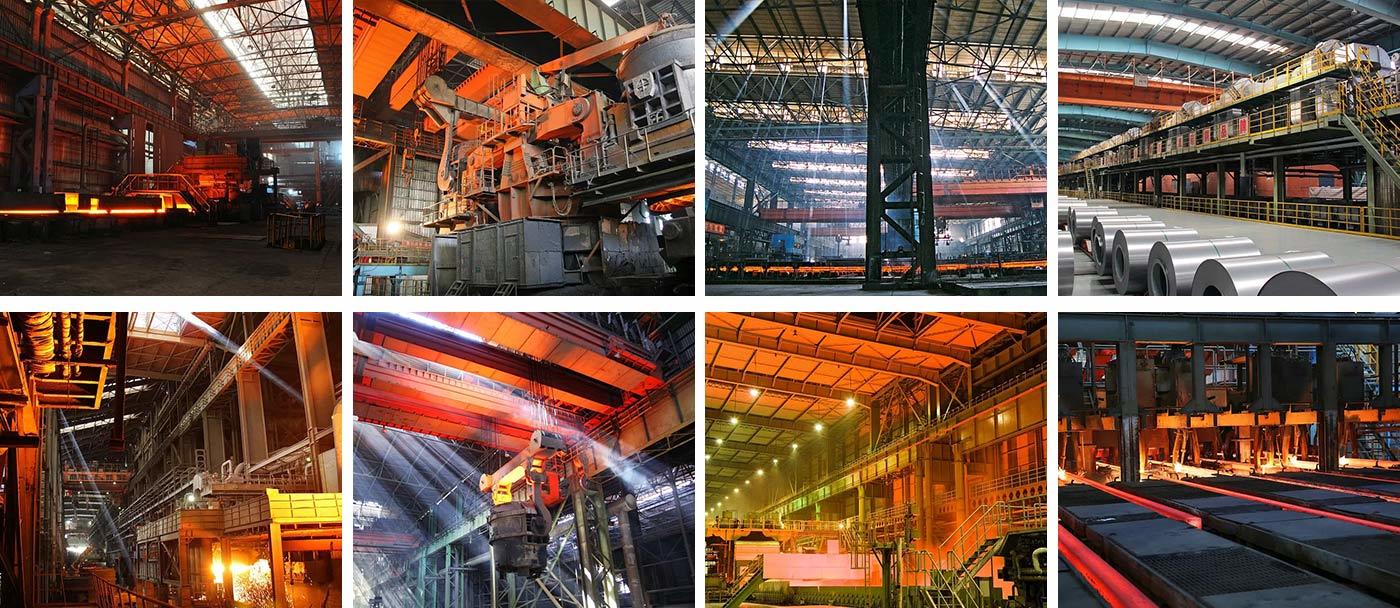

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE