ASME SA213 T11 Seamless Alloy Steel Tubes

chedules: 20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier

Standard: ASME SA213

Grade: ASME A213 T11

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Product introduction

ASTM A213 T11 is the part of ASTM A213 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler,

Superheater, Heat-Exchanger Tubes.

ASTM A213 Alloy Steel T11 Pipes is also extremely recognized by our customers for rigid construction, high performance,

corrosion resistance, durability and precise dimensions.By providingASME SA 213 Alloy Steel T11 Pipes, we have been

fulfilling the requirements of the automotive, oil and gas industries, power plants,shipbuilding, and more.

| Size Range | 1/8" –42” |

| Schedules | 20, 30, 40, Standard (STD), Extra Heavy (XH), 80, 100, 120, 140, 160, XXH & heavier |

| Standard | ASME SA213 |

| Grade | ASME A213 T11 |

| Alloy Steel Tube in Grade | ASTM A 213 – T-2, T-5, T-9, T-11, T-12, T-22, Etc. (with IBR Test Certificate) ASTM A 209 – T1 , Ta, T1b |

| In Length of | Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

| Value Added Service | Draw & Expansion as per required Size & Length Heat Treatment, Bending, Annealed, Machining Etc. |

| End Connections | Plain, Bevel, Screwed, Threaded |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Test Certificate | Manufacturer Test Certificate, IBR Test Certificate, Laboratory Test Certificate from Govt. Approved Lab Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports, India Boiler Regulations (IBR) Test Certificate |

| ASTM A213 T11 / ASME SA213 T11 Alloy Steel Tube Form |

Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes, special shape tube etc. |

| ASTM A213 T11 / ASME SA213 T11 Alloy Steel Tube End |

Plain End, Beveled End, Threaded |

| Specialize | ASTM A213 T11 Heat Exchanger & Condenser Tubes |

| Outside Coating | Black Painting, Anti-Corrosion Oil, Galvanised Finish, Finish as per customer Requirements |

SA213 T11 Alloy Steel Tube Applications

Oil and Gas Drilling

Catering to domestic or industrial needs

conveyance of fluids intended for critical high temperatures

general corrosion service applications

heat transfer process equipment like Boilers, Heat Exchangers

General Engineering and Process Instrumentation applications

Technical data

Chemical Composition(%) for ASTM A213 T11 Low Alloy Steel

| UNS Designation | K11597 |

| Carbon | 0.05–0.15 |

| Manganese | 0.30–0.60 |

| Phosphorus | 0.025 |

| Sulfur | 0.025 |

| Silicon | 0.50–1.00 |

| Nickel | … |

| Chromium | 1.00–1.50 |

| Molybdenum | 0.44–0.65 |

| Vanadium | … |

| Boron | … |

| Niobium | … |

| Nitrogen | … |

| Aluminum | … |

| Tungsten | … |

| Other Elements | … |

Mechanical properties for ASTM A213 T11 Low Alloy Steel

| Tensile strength(min) | 415Mpa |

| Yield strength(min) | 220Mpa |

| Elongation | 30% |

| Delivery condition | annealed |

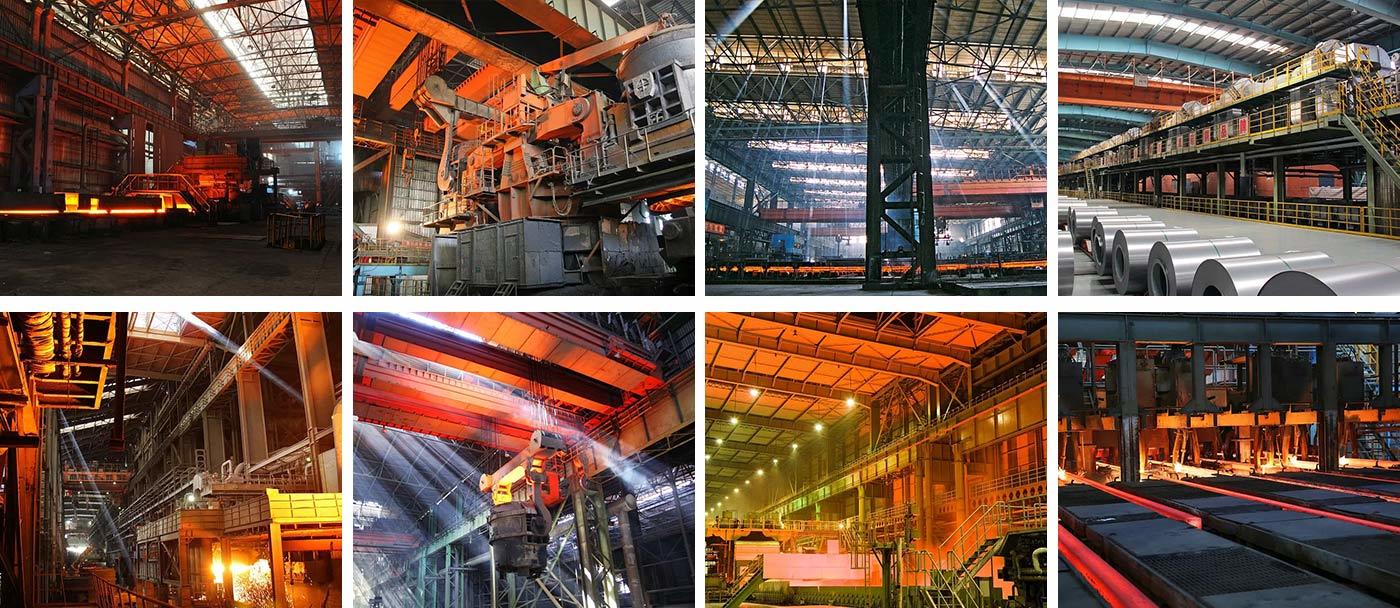

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE