5140 Steel Plate 1.7035 41Cr4 SCr440 Alloy Steel

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

1. Supply Range of AISI/ASTM 5140

Round Bar: diameter 20mm – 300mm

Steel Plate and Steel Block: thickness 10-200mm x width 300-2000mm

10-80mm thickness 5140 plate are available all the time in stock,

90-200mm thickness plate to be newly production in 15-30 days lead time.

Surface Finish: Black Surface, Milled Surface or Polished Surface as per given requirements.

2. Relevant AISI 5140 Specification and Equivalent Steel Grades

| Country | USA | German | Japan |

| Standard | ASTM/AISI A29 | EN 10083-3 | JIS G4053 |

| Grades | 5140 | 41Cr4 | SCr440 |

3. ASTM 5140 Material Chemical Composition and Equivalent

| Standard | Grade/Steel Number | C | Mn | P | S | Si | Cr | Ni |

| ASTM A29 | 5140 | 0.38-0.43 | 0.70-0.90 | ≤0.035 | ≤0.040 | 0.15-0.35 | 0.70-0.90 | – |

| EN 10083-3 | 41Cr4 / 1.7035 | 0.38-0.45 | 0.60-0.90 | ≤0.025 | ≤0.035 | ≤0.40 | 0.90-1.20 | – |

| JIS G4053 | SCr440 | 0.38-0.43 | 0.60-0.90 | ≤0.030 | ≤0.030 | 0.15-0.35 | 0.90-1.20 | ≤0.25 |

4. AISI 5140 Steel Properties

| Property | Value in metric unit | Value in US unit | ||

| Density | 7.872 *10³ | kg/m³ | 491.4 | lb/ft³ |

| Modulus of elasticity | 205 | GPa | 29700 | ksi |

| Thermal expansion (20 ºC) | 12.6*10-6 | ºCˉ¹ | 7.00*10-6 | in/(in* ºF) |

| Specific heat capacity | 452 | J/(kg*K) | 0.108 | BTU/(lb*ºF) |

| Thermal conductivity | 44.7 | W/(m*K) | 310 | BTU*in/(hr*ft²*ºF) |

| Electric resistivity | 2.28*10-7 | Ohm*m | 2.28*10-5 | Ohm*cm |

| Tensile strength (annealed) | 572 | MPa | 83000 | psi |

| Yield strength (annealed) | 293 | MPa | 42500 | psi |

| Elongation (annealed) | 29 | % | 29 | % |

| Hardness (annealed) | 85 | RB | 85 | RB |

| Tensile strength (normalized) | 793 | MPa | 115000 | psi |

| Yield strength (normalized) | 472 | MPa | 68500 | psi |

| Elongation (normalized) | 23 | % | 23 | % |

| Hardness (normalized) | 98 | RB | 98 | RB |

5. Forging of 5140 Alloy Steel

Hot forming temperature: 1050-850℃.

6. ASTM 5140 Steel Heat Treat

Soft Annealing

Heat to 680-720℃, cool slowly. This will produce a maximum 5140 hardness of 241HB (Brinell hardness).

Noramlizing of steel grade 5140

Temperature: 840-880℃.

Hardening of 5140 forged steel

Harden from a temperature of 820-850, 830-860℃ followed by water or oil quenching.

Tempering of SAE 5140 material

Tempering temperature: 540-680℃.

7. Applications of AISI Grade 5140

AISI 5140 steel can be used for low and moderately stressed parts for vehicles, engines and machines where hard, wear resisting surface is needed. Hardness as surface hardened about 54 HRC. SAE 5140 steels can also be for marine engineering industry, chemical processing plants, boiler & pressure vessels, nuclear power plants etc.

If you have queries about the 5140 specs, or any questions about the 5140 vs 4130, 5140 vs 4340 etc, please contact us for technical support any time.

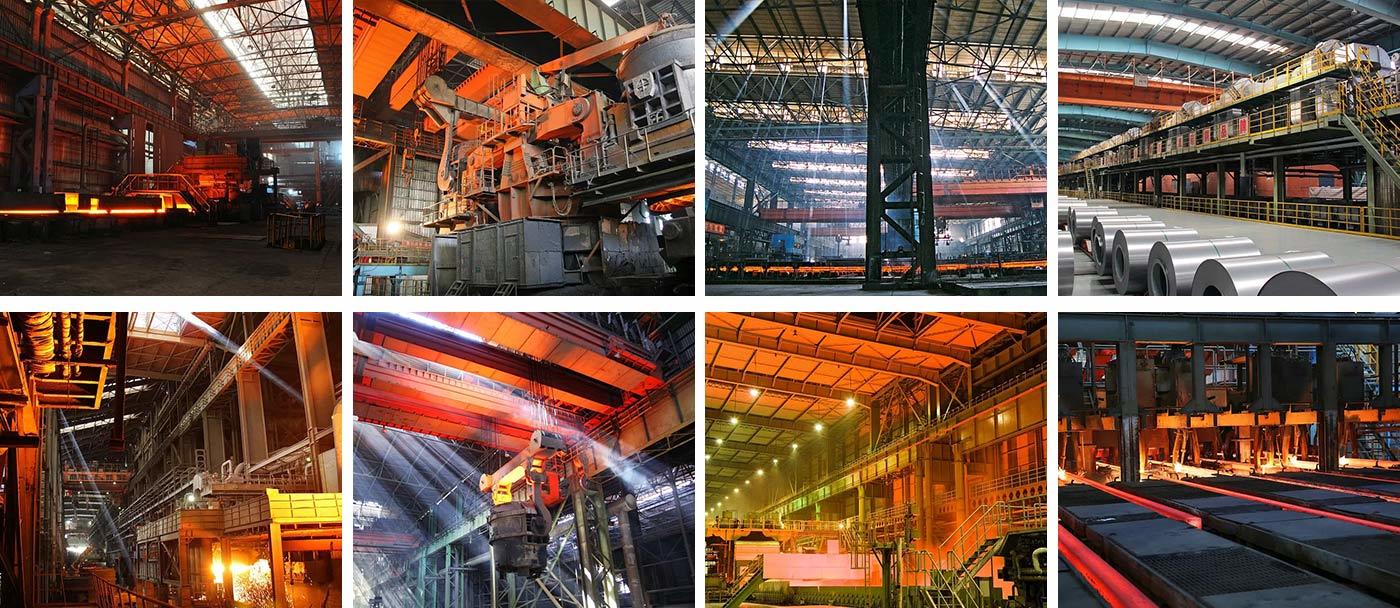

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE