DIN2391 Cold drawn Seamless Steel pipe and tube

enhanced machinability and increased strength and tolerances compared to hot-rolled products.

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Product introduction

Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts.

|

Material |

10#,20#,35#,45#;16Mn;20Cr,40Cr;15CrMo,30CrMo,35CrMo,42CrMo;A106B,St37,St42,ASTM 4140 etc. |

|||

|

Technique |

Cold Rolled/Cold Drawn/Hot Rolled |

|||

|

Wall Thickness |

1-25mm |

|||

|

Out Diameter |

10-325mm |

|||

|

Application |

Structure pipe; High and low pressure boiler tube; Liquid delivery; Seamless steel pipe for petroleum cracking ,Oil pipe,Gas pipe |

|||

|

Payment |

TT/LC |

|||

|

Surface |

Customer's Requirement |

|||

|

MOQ |

1 ton for normal material |

|||

Cold Drawn Seamless Mechanical Tubing

Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

Condition on delivery:

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) |

BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) |

BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

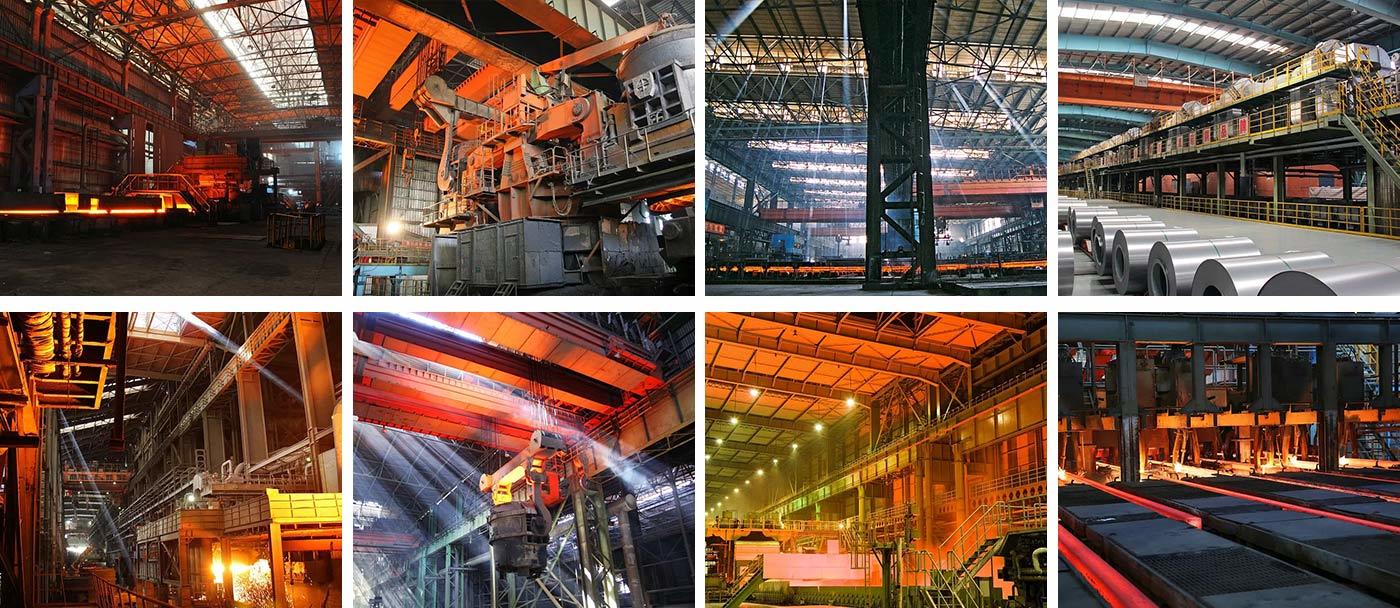

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE