416HT Stainless Steel Sheet

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Product introduction

Type 416HT Stainless Steel is a stainless steel which is martensitic and has been hardened by heat treatment to higher strength and hardness levels. It has much better machining properties than the austenitic grades, but lower corrosion resistance.It has the highest machinability of any stainless steel at about 85% of that of a free-machining carbon steel. Martensitic stainless steels were designed to be hardenable by heat treatment and also corrosion resistant. Although Alloy 416HT and other martensitic stainless steels are not as resistant as austenitic or ferritic stainless, it still demonstrates good corrosion and oxidation resistance plus high strength in the hardened and tempered condition. Alloy 416HT is easily machined, is always magnetic, and has low frictional properties that reduce galling and seizing.

|

Thickness(mm) |

0.2-200mm |

|

Width(mm) |

600-2500mm |

|

Grade |

200 Series/300Series/400Series/500Series/600Series |

|

Color |

White Bright |

|

Surface |

2B, BA, No.4, HL, Mirror, 8K |

|

Standard |

201, 202, 301, 302, 303, 304, 304L, 316, 316L, 316N, 321, 309S, 310S, 317L, 904L, 409L |

|

Edge |

Mill Edge Slit Edge |

|

Packing |

Export Standard |

|

Temper |

Full hard, half hard, soft |

|

Sample |

Provided within 3 Days |

|

Technique |

Hot Rolled/Cold Rolled |

|

Application |

Bridges,shipbuilding,automobiles,structural steel plates,springs,etc. |

Technical data

Applications:

Alloy 416HT is generally used for parts that are extensively machined and require the corrosion resistance of a 13% chromium stainless steel. Applications that generally use Alloy 416 include:

- Electrical motors

- Nuts and bolts

- Pumps

- Valves

- Automatic screw machine parts

- Washing machine components

- Studs

- Gears

Standards:

- ASTM/ASME: UNS S41600

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

Corrosion Resistance:

- Demonstrates corrosion resistance to natural food acids, waste products, basic and neutral salts, natural waters, and most atmospheric conditions

- Less resistant that the austenitic grades of stainless steel and also the 17% chromium ferritic alloys

- High sulfur, free-machining grades like Alloy 416HT are unsuitable for marine or other chloride exposure

- Maximum corrosion resistance is achieved in the hardened condition, with a smooth surface finish

Heat Resistance

- Fair resistance to scaling in intermittent service up to 1400oF (760oC) and up to 1247oF (675oC) in continuous service

- Not recommended for use in temperatures above the relevant tempering temperature if maintenance of mechanical properties is important

Welding Characteristics

- Poor weldability

- If welding is necessary use Alloy 410 low hydrogen electrodes

- Pre-heat to 392 to 572°F (200-300°C)

- Follow immediately with annealing or re-hardening, or a stress relief at 1202 to 1247°F (650 to 675°C)

Machinability

- Has outstanding machinability

- Best machinability is in the sub-critical annealed condition

Chemical Properties:

| C | Mn | Si | P | S | Cr | |

|---|---|---|---|---|---|---|

| 416HT | 0.15 max |

1.25 max |

1.00 max |

0.06 max |

0.15 max |

min: 12.0 max: 14.0 |

Mechanical Properties:

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) |

Elongation (% in 50mm) |

Hardness Brinell (HB) |

Impact Charpy V (J) |

|---|---|---|---|---|---|

| Annealed * | 517 | 276 | 30 | 262 | – |

| Condition T ** | 758 | 586 | 18 | 248-302 | – |

| 204 | 1340 | 1050 | 11 | 388 | 20 |

| 316 | 1350 | 1060 | 12 | 388 | 22 |

| 427 | 1405 | 1110 | 11 | 401 | # |

| 538 | 1000 | 795 | 13 | 321 | # |

| 593 | 840 | 705 | 19 | 248 | 27 |

| 650 | 750 | 575 | 20 | 223 | 38 |

| * Annealed properties are typical for Condition A of ASTM A582. | |||||

| ** Hardened and tempered Condition T of ASTM A582 – Brinell Hardness is specified range, other properties are typical only. | |||||

| # Due to associated low impact resistance this steel should not be tempered in the range 400- | |||||

Physical Properties:

| Density kg/m3 |

Thermal Conductivity W/mK |

Electrical Resistivity (Microhm/cm) |

Modulus of Elasticity |

Coefficient of Thermal Expansion µm/m/°C |

Specific Heat (J/kg.K) |

Specific Gravity |

|---|---|---|---|---|---|---|

| 7750 | 24.9 at 212°F | 43 at 68°F | 200 GPa | 9.9 at 32 – 212°F | 460 at 32°F to 212°F | 7.7 |

| 28.7 at 932 °F | 11.0 at 32 – 599°F | |||||

| 11.6 at 32-1000°F |

FAQ

Q:Will you delivery the goods on time?

A:Yes,we promise to provide best quality products and delivery on time.Honesty is our company's tenet.

Q:Do you provide samples?is it free or extra?

A:The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q:Do you accept the third party inspection?

A:Yes absolutely we accept.

Q:What are your main products?

A:Carbon steel,alloy steel,stainless steel plate/coil,pipe and fittings,sections etc.

Q:Can you accept the order of customzied?

A:Yes,we assure.

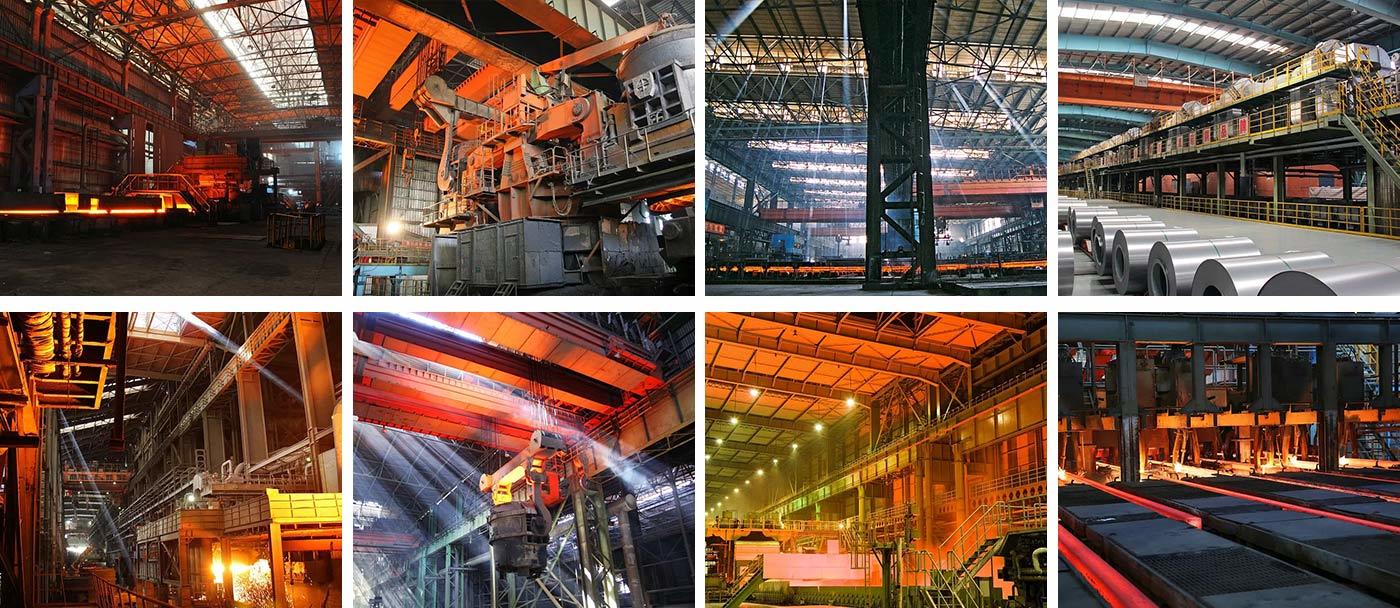

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE