API 5CT casing pipe

Technique: Seamless/EW

Standard: API 5CT

Out Diameter (OD): 114.3-508mm

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Product introduction

Casing is large diameter pipe that is assembled and inserted into a recently drilled section of a borehole and typically

held into place with cement. And we provide various Seamless Casing from 4-1/2’’-20’’ in grade H40, J55, K55,

N80, L80, C95, P110 etc. The Casing length range is R1, R2, R3, with threads of BTC, LTC, STC. According to the strength

of steel casing can be divided into different steel grade, deep well, using different steel grade. In corrosive environment

also requires the casing itself has corrosion resistance. In the complicated geologic condition place also asked the casing

having an anti-collapse performance.

| Product Name | API Spec 5CT Casing Pipe |

| Material | H40 J55 K55 N80 M65 L80 L8013CR C90 C95 T95 P110 Q125 V150 |

| Technique | Seamless/EW |

| Standard | API 5CT |

| Out Diameter (OD) | 114.3-508mm |

| Wall Thickness (WT) | 5.21-22.22mm |

| Norminal Weight | 9.5-133.0(Ib/ft) |

| Length | R1 (5.49-6.71m), R2 (8.23-9.14m), R3 (11.58-13.72m) or as customer's requirements |

| Coupling | BTC, STC, LTC, NUE, EUE, VAM, BU or no thread |

| Usage | Oil/Gas Drilling |

| Outer Diameter | Wall Thickness | Thread | Length | ||

| in | mm | kg/m | lb/ft | ||

| 4 1/2" | 114.3 | 14.14-22.47 | 9.50-15.10 | LTC/STC/BTC | R1/R2/R3 |

| 5" | 127 | 17.11-35.86 | 11.50-24.10 | LTC/STC/BTC | R1/R2/R3 |

| 5 1/2" | 139.7 | 20.83-34.23 | 14.00-23.00 | LTC/STC/BTC | R1/R2/R3 |

| 6 5/8" | 168.28 | 29.76-35.72 | 20.00-24.00 | LTC/STC/BTC | R1/R2/R3 |

| 7" | 177.8 | 25.30-56.55 | 17.00-38.00 | LTC/STC/BTC | R1/R2/R3 |

| 7 5/8" | 193.68 | 35.72-63.69 | 24.00-42.80 | LTC/STC/BTC | R1/R2/R3 |

| 8 5/8" | 219.08 | 35.72-72.92 | 24.00-49.00 | LTC/STC/BTC | R1/R2/R3 |

| 9 5/8" | 244.48 | 48.07-86.91 | 32.30-58.40 | LTC/STC/BTC | R1/R2/R3 |

| 10 3/4" | 273.05 | 48.73-97.77 | 32.75-65.70 | LTC/STC/BTC | R1/R2/R3 |

| 11 3/4" | 298.45 | 62.50-89.29 | 42.00-60.00 | LTC/STC/BTC | R1/R2/R3 |

| 13 3/8" | 339.72 | 71.43-107.15 | 48.00-72.00 | LTC/STC/BTC | R1/R2/R3 |

| 16'' | 406.4 | 96.73-162.21 | 65.00-109.00 | LTC/STC/BTC | R1/R2/R3 |

| 18 5/8'' | 473.08 | 130.21 | 87.50 | LTC/STC/BTC | R1/R2/R3 |

| 20'' | 508 | 139.89-197.93 | 94.00-133.00 | LTC/STC/BTC | R1/R2/R3 |

Technical data

Chemical Composition

| Group | Grade | Type | C | Mn | Mo | Cr | Ni max. | Cu max. | P max. | S max. | Si max. | ||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a The carbon content for L80 may be increased up to 0.50 % maximum if the product is oil-quenched. b The molybdenum content for Grade C90 Type 1 has no minimum tolerance if the wall thickness is less than 17.78 mm. c The carbon content for R95 may be increased up to 0.55 % maximum if the product is oil-quenched. d The molybdenum content for T95 Type 1 may be decreased to 0.15 % minimum if the wall thickness is less than 17.78 mm. e For EW Grade P110, the phosphorus content shall be 0.020 % maximum and the sulfur content 0.010 % maximum. NL = no limit. Elements shown shall be reported in product analysis. |

|||||||||||||||

Mechanical Properties

| Standard | Type | Tensile Strength MPa |

Yield Strength MPa |

Hardness Max. |

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Warehouse storage

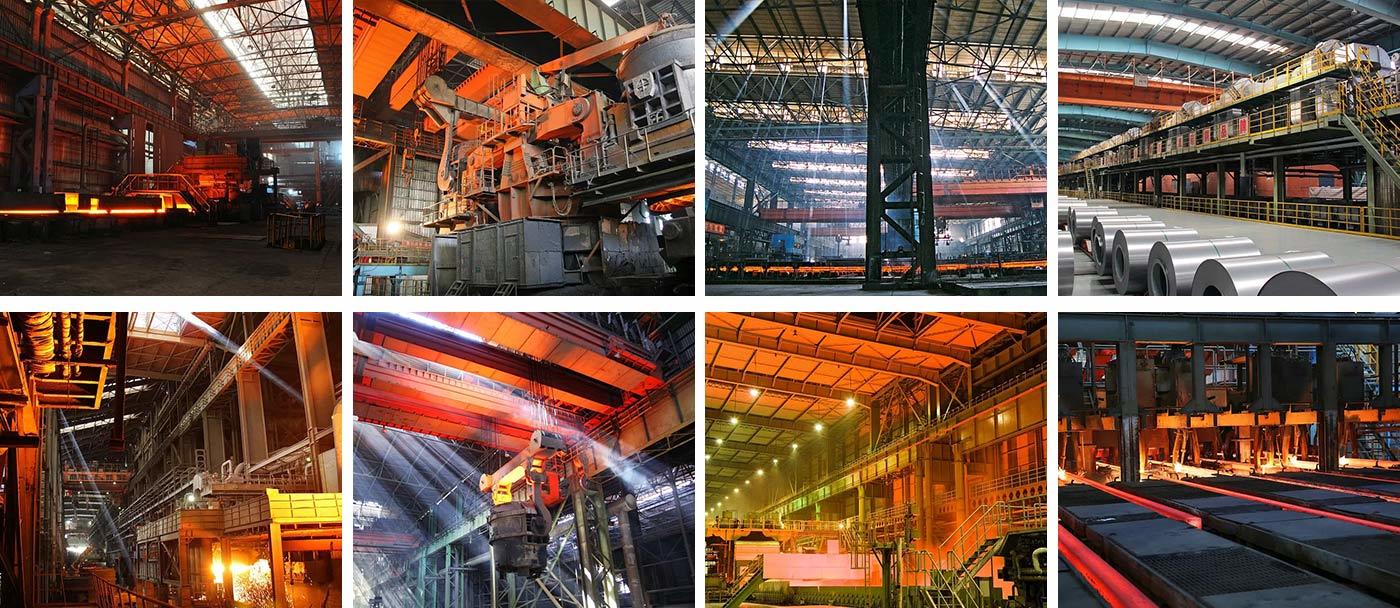

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE