201 Stainless Steel Coil

no bubbles, no pinholes and other characteristics. It is a high-quality material for the production

of various watch cases, strap and bottom covers.

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

201 Stainless Steel Coil Strip Specifications:

|

Grade |

201,202,301,304,309,309s,316,316L,405,409,410,431,440C,441,904L,2205,2507 |

|

Standard |

AISI, ASTM, DIN, GB, JIS, SUS |

|

Thickness |

Hot rolled: 0.1-12mm or as your request |

|

Cold rolled: 0.3 / 0.5 / 0.6 / 0.7 / 0.8 / 0.9 / 1.0 / 1.2 / 1.5 / 1.8 / 2.0 / 2.5 / 3.0mm or as your request |

|

|

Width |

Hot rolled: 1000 / 1219 / 1500 / 1800 / 2000mm or as your request |

|

Cold rolled: 1030 / 1250 / 1540 / 1840 / 2040mm or as your request |

|

|

Treatment/Technique |

Hot rolled, Cold rolled |

|

Surface |

NO.1, 2B, 8K, 2D, BA, NO.4, HL... |

|

Applications |

Decorative /industrial/building material |

|

Trade Terms |

EXW, FOB, CFR, CIF |

|

Delivery time |

Shipped in 7-15 days after payment |

|

Package |

Standard sea-worthy package or as required |

|

Seaworthy Packing |

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM |

|

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM |

|

|

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

Chemical Composition of 201 Stainless Steel Coil:

| Grade |

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

|

201 |

≤0 .15 |

≤0 .75 |

5. 5-7. 5 |

≤0.06 |

≤ 0.03 |

3.5 -5.5 |

16.0 -18.0 |

- |

|

202 |

≤0 .15 |

≤L.0 |

7.5-10.0 |

≤0.06 |

≤ 0.03 |

4.0-6.0 |

17.0-19.0 |

- |

|

301 |

≤0 .15 |

≤L.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

6.0-8.0 |

16.0-18.0 |

- |

|

302 |

≤0 .15 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

8.0-10.0 |

17.0-19.0 |

- |

|

304 |

≤0 .0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

8.0-10.5 |

18.0-20.0 |

- |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0-13.0 |

18.0-20.0 |

- |

|

309S |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0-15.0 |

22.0-24.0 |

- |

|

310S |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.035 |

≤ 0.03 |

19.0-22.0 |

24.0-26.0 |

|

|

316 |

≤0.08 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

|

316L |

≤0 .03 |

≤1.0 |

≤2.0 |

≤0.045 |

≤ 0.03 |

12.0 -15.0 |

16 .0 -1 8.0 |

2.0 -3.0 |

|

321 |

≤ 0 .08 |

≤1.0 |

≤2.0 |

≤0.035 |

≤ 0.03 |

9.0 - 13 .0 |

17.0 -1 9.0 |

- |

|

630 |

≤ 0 .07 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

3.0-5.0 |

15.5-17.5 |

- |

|

631 |

≤0.09 |

≤1.0 |

≤1.0 |

≤0.030 |

≤0.035 |

6.50-7.75 |

16.0-18.0 |

- |

|

904L |

≤ 2 .0 |

≤0.045 |

≤1.0 |

≤0.035 |

- |

23.0·28.0 |

19.0-23.0 |

4.0-5.0 |

|

2205 |

≤0.03 |

≤1.0 |

≤2.0 |

≤0.030 |

≤0.02 |

4.5-6.5 |

22.0-23.0 |

3.0-3.5 |

|

2507 |

≤0.03 |

≤0.8 |

≤1.2 |

≤0.035 |

≤0.02 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

|

2520 |

≤0.08 |

≤1.5 |

≤2.0 |

≤0.045 |

≤ 0.03 |

0.19 -0. 22 |

0. 24 -0 . 26 |

- |

|

410 |

≤0.15 |

≤1.0 |

≤1.0 |

≤0.035 |

≤ 0.03 |

- |

11.5-13.5 |

- |

|

430 |

≤0.1 2 |

≤0.75 |

≤1.0 |

≤ 0.040 |

≤ 0.03 |

≤0.60 |

16.0 -18.0 |

- |

201 stainless steel coil is mainly used as decorative pipe, industrial pipe and some shallow stretched products.201 stainless steel coil is mainly used for high temperature applications. High temperature applications require strong sensitization resistance to prevent intergranular corrosion at lower temperatures.

Stainless Steel Surface & Applications:

Stainless steel has a variety of surfaces, please contact us for confirmation.

|

Surface Finish |

Definition |

Application |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe. |

Warehouse storage

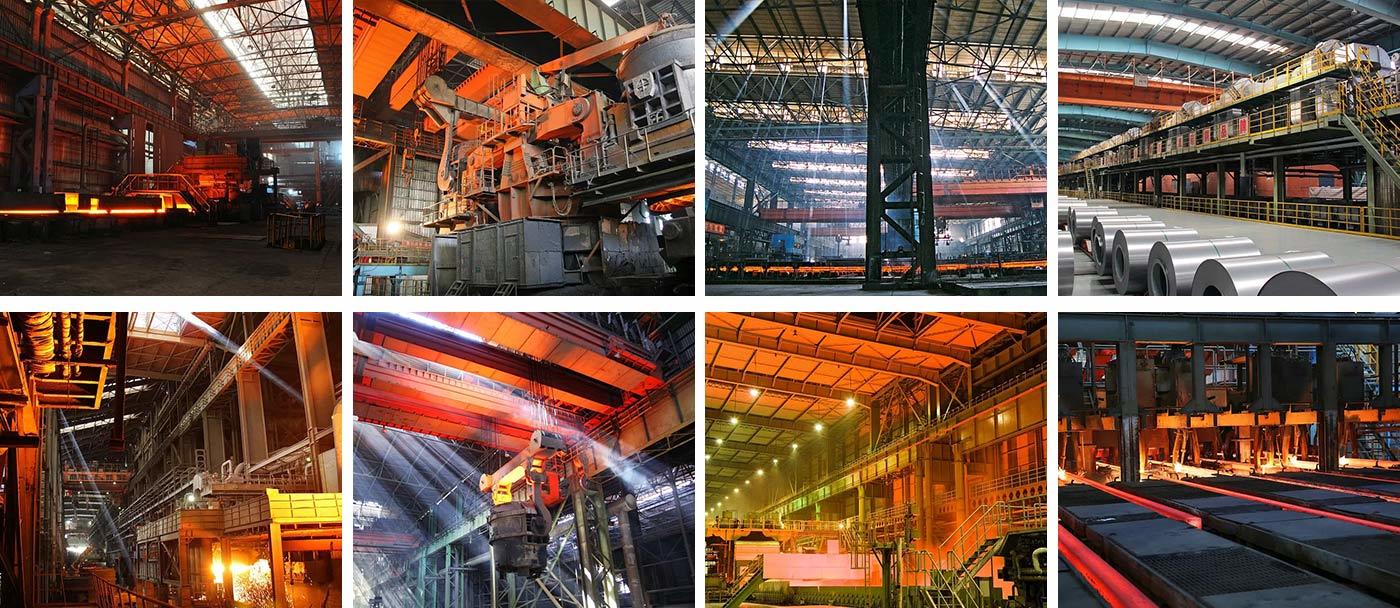

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE