AISI 316/316L STAINLESS STEEL

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Product information

The Difference Between 316 and 316L Stainless Steel

The difference between 316 and 316L stainless steel is that 316L has a .03 max carbon and is good for welding whereas 316 has a mid range level of carbon.

316 and 316L are austenitic alloys, meaning that these stainless steel products gain corrosion resistance from use of a nonmagnetic solid solution of ferric carbide or carbon in iron in the manufacturing process.

In addition to chromium and nickel, these alloys contain molybdenum, which also makes them more corrosion resistant. Even greater corrosion resistance is delivered by 317L, in which molybdenum content increases to 3 to 4% from the 2 to 3% found in 316 and 316L.

Properties and Uses of 316 and 316L Stainless Steel

These alloys are known for their excellent welding properties, joined by both fusion and resistance processes. The 316L low carbon version is preferred in corrosive environments. It is important to make sure that copper and zinc do not become contaminants at the site of welds, as this can create cracking.

It is common to fabricate 316 and 316L into many different shapes. They may be formed on equipment similar to carbon steel, and are readily blanked and pierced. Excellent malleability means they perform well in deep drawing, spinning, stretching and bending.

Technical data

Mechanical properties

| Type | UTS | Yield | Elongation | Hardness | Comparable DIN number | |

| N/mm | N/mm | % | HRB | wrought | cast | |

| 304 | 600 | 210 | 60 | 80 | 1.4301 | 1.4308 |

| 304L | 530 | 200 | 50 | 70 | 1.4306 | 1.4552 |

| 316 | 560 | 210 | 60 | 78 | 1.4401 | 1.4408 |

| 316L | 530 | 200 | 50 | 75 | 1.4406 | 1.4581 |

Chemical Composition

|

AISI 316 (1.4401) |

AISI 316L (1.4404) |

AISI 316LN (1.4406) |

|

|

Cr (Chromium) |

16.5 – 18.5 % |

16.5 – 18.5 % |

16.5 – 18.5 % |

|

Ni (Nickel) |

10 - 13 % |

10 - 13 % |

10 – 12.5 % |

|

Mn (Manganese) |

<= 2 % |

<= 2 % |

<= 2 % |

|

Mo (Molybdenum) |

2 – 2.5 % |

2 – 2.5 % |

2 – 2.5 % |

|

Si (Silicon) |

<= 1 % |

<= 1 % |

<= 1 % |

|

N (Nitrogen) |

0.11 % |

0.11 % |

0.12-0.22 % |

|

P (Phosphorus) |

0.045 % |

0.045 % |

0.045 % |

|

C (Carbon) |

<= 0.07 % |

<= 0.03 % |

<= 0.03 % |

|

S (Sulphur) |

0.03 % |

0.02 % |

0.015 % |

Among all steels,austenitic stainless steel has the lowest yield point.Therefore,considering the mechanical properties, austenitic stainless steel is not the best material for the stem, because to ensure a certain strength, the diameter of the stem will increase. Yield point can not be improved by heat treatment,but can be improved by cold forming.

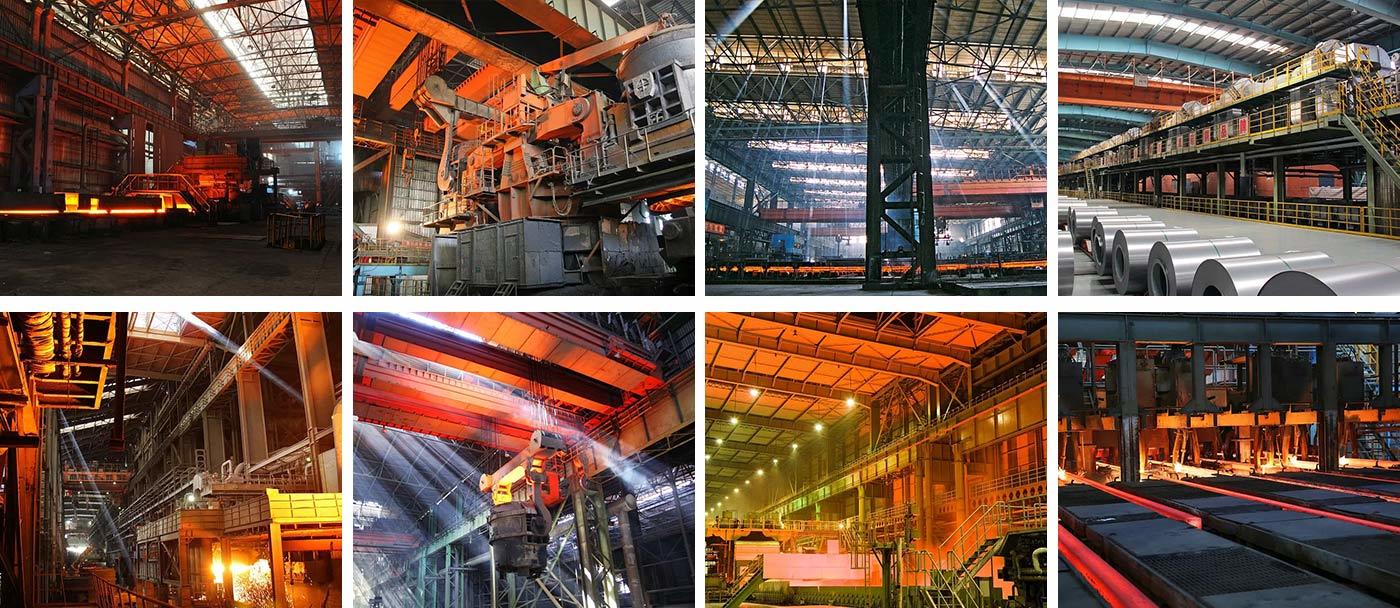

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE