ABS Grade A Shipbuilding Steel Plate

and must be able to resist corrosive effects that are common in a water environment.

To achieve this, special alloying elements are added to these grades in order to defend agaist corrosion.

While most carbon steel is not suited for marine environments, there are several marine grade carbon

steels that have been approved by the different societies for shipbuilding applications.

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

Structural steel for ship hulls is divided into strength classes according to its minimum yield strength: general strength structural steel and high strength structural steel. Maine steel plate refers to hot rolled steel plate produced in accordance with the requirements of the classication society for the construction of ship hull structures.

There are 9 main classification societies in worldwide

A.B.S American Bureau of Shipping

B.V. Bureau Veritas

C.C.S. China Classification Society

D.N.V Det Norske Veritas

G.L. Germanischer Lloyd

K.R. Korean Register of Shipping

L.R. Lloyd’s Register of Shipping

N.K. Nippon Kaiji Kyokai

R.I.N.A Registro Italiano Navale

ABS for American Bureau of Shipping is also known as A131, which is used almost exclusively in shipbuilding. It has a minimum yield of 34ksi(235Mpa). It is used in barges, ship construction and marine equipment.

Grade A steel is the impact force subjected to normal temperature(20 ° C).

Grade B steel impact force at 0 ° C

Grade D steel impact force at -20 ° C

Grade E steel impact force at -40 ° C

Shot blasting service

Shot blasting is a method used to clean or polish steel when enhanced surface finishes are required. Shot blasting is used in almost every industry we serve. Especially in shipbuilding, rail,structural fabrication and more.

Specifications range

Thickness:2.5-120mm

Width:1000-3000mm

Length: As request

| Steel grade | C | Si | Mn | P | S | Als |

| Grade A | ≤0.21 | ≤0.50 | ≥2.5C | ≤0.035 | ≤0.035 | - |

| Grade B | ≤0.21 | ≤0.35 | 0.8-1.2 | ≤0.035 | ≤0.035 | - |

| Grade D | ≤0.21 | ≤0.35 | 0.6-1.2 | ≤0.035 | ≤0.035 | ≥0.015 |

| Grade E | ≤0.18 | ≤0.35 | 0.7-1.2 | ≤0.035 | ≤0.035 | ≥0.015 |

Processing for Different Grades

Grade A and B

The general strength of grade A and B shipbuilding steel plates can meet the requirements of process and mechanical properties through ordinary rolling, so the production process is relatively simple.

Grade D, E (DH32, DH36, EH 32, EH 36)

Grade D and E series (inlcuding AH32/36, DH32, DH36, EH32, EH36) shipbuilding steel plates require good low temperature toughness and good welding performance. The production high-strength shipbuilding steel plate needs to be normalized by means of controlled rolling and controlled cooling or heat treatment processes with more complete equipment. At the same time, the internal steel purity of the supplied billets is required to be high, especially the content of S, P, N, 0 and H in the steel should be strictly controlled.

Alloy Elements Added to Improve Toughness

In order to ensure the performance of high-strength ship plates, micro-alloying technology is adopted. By adding Nb, V, Ti and other alloying elements to the steel, combined with the controlled rolling process, the grain is refined and the toughness is improved.

Direction of Development for Shipbuilding Plate

High strength, high specification, with the ship's large-scale and safety, and changes in coating specifications, the demand for ordinary A-class panels is gradually reduced, and the demand for high-strength panels is increasing, which is concentrated in large ships of 5m wide. Plate, 200-300mm thickness special thick ship board.

Mechanical Properties

| Steel grade | Thickness/mm | Yield point/MPa | Tensile point /MPa | Elongation/% | Temperature/° C | V-type impact test | |

| Akv/J | |||||||

| Vertical | Horizontal | ||||||

| Grade A | ≤50 | ≥235 | 400-490 | ≥22 | - | - | - |

| Grade B | ≤50 | ≥235 | 400-490 | ≥22 | 0 | ≥27 | ≥20 |

| Grade D | ≤50 | ≥235 | 400-490 | ≥22 | -10 | ≥27 | ≥20 |

| Grade E | ≤50 | ≥235 | 400-490 | ≥22 | -40 | ≥27 | ≥20 |

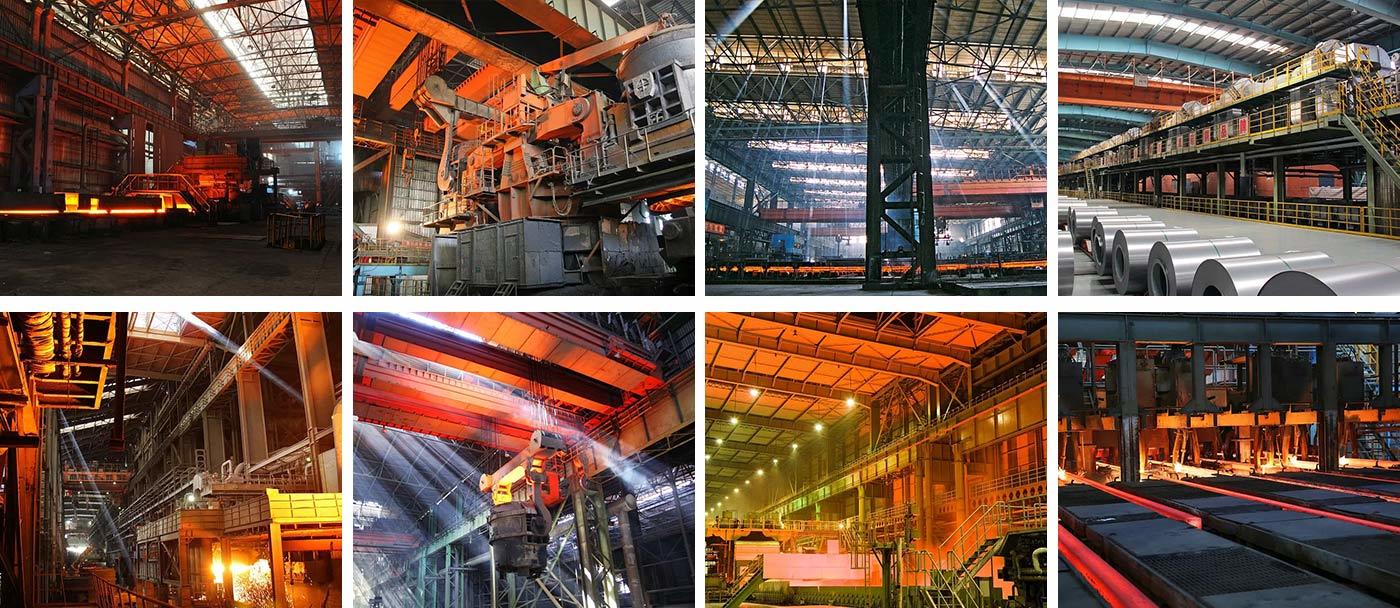

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE