ASME SA387 GR.22 CL2 Boiler and Pressure Vessel Steel plate

Classification :

Keywords: Handheld refractometer

PRODUCT DETAILS

ASME SA387 GR.22 CL2 Pressure Vessel Steel plate Descriptions:

SA 387 GR.22 CL.2 PLATE is having chromium of 2.25% and molybdenum of 1% and ability to work in 600 Deg C temperatures surrounding effectively. The molybdenum and chromium steel plates are working effectively at different temperature continually offering best performance. The addition of molybdenum in SA 387 alloy is increasing the tensile strength of the plates at greater temperature. Also, it is providing excellent corrosion resistance ability and oxidation as well by increasing the lattice strain. This is effectively stopping the corrosive agent from iron dissolving and gives good heat resistance ability and becomes a good choice for gas surrounding. Also, it has good weldability. Thus, this plate is highly demanded globally.

Chemical Composition and Mechanical Properties:

| SA387 Gr.22 CL.2 Chemical Composition | |||||||

| Grade | The Element Max (%) | ||||||

| C | Si | Mn | P | S | Cr | Mo | |

| SA387 Gr.22 Cl.2 | 0.04-0.15 | 0.50 | 0.30-0.60 | 0.035 | 0.035 | 1.88-2.62 | 0.85-1.15 |

| Grade | SA387 Gr.22 CL.2 Mechanical Property | |||

| Thickness | Yield | Tensile | Elongation | |

| SA387 Gr.22 Cl.2 | mm | Min Mpa | Mpa | Min % |

| t≦50 | 310 | 515-690 | 18 | |

| 50<t≦200 | - | - | - | |

Refered Standards for ASME SA387 Alloy Steel Plate

ASME

- SA20/A20M: General requirements for pressure vessel plates.

- SA370: Test specification for mechanical properties of steel

- SA435/A435M: For straight-beam ultrasonic examination of steel plates

- SA577/A577M: For ultrasonic angle beam examination of steel plates

- SA578/A578M: For straight beam UT examination of rolled steel plates in special applications

- SA1017/A1017M: Specification for pressure vessle plates of alloy steel, chromium-molybdenum-tungsten

AWS Specification

- A5.5/A5.5M: Low alloy steel electrodes for shield metal arc welding.

- A5.23/A5.23M: Low alloy steel electrodes for fulxes for submerged arc welding.

- A5.28/A5.28M: For gas shielded arc welding

- A5.29/A5.29M: For flux cored arc welding.

Heat Treatment for SA387 Chrom Moly Alloy Steel Plate

Chrome moly alloy steel plate under ASME SA387 shall be killed steel, with thermally treated either by annealing, normarlizing and tempering. Or in case agreed by buyer, accelerated cooling from the austenitizing temperature by air blasting or liquid quenching, followed by tempering, minimum tempering temperatures shall be as below table:

| Grade | Temperature, °F [°C] |

| 2, 12 and 11 | 1150 [620] |

| 22, 22L, 21, 21L and 9 | 1250 [675] |

| 5 | 1300 [705] |

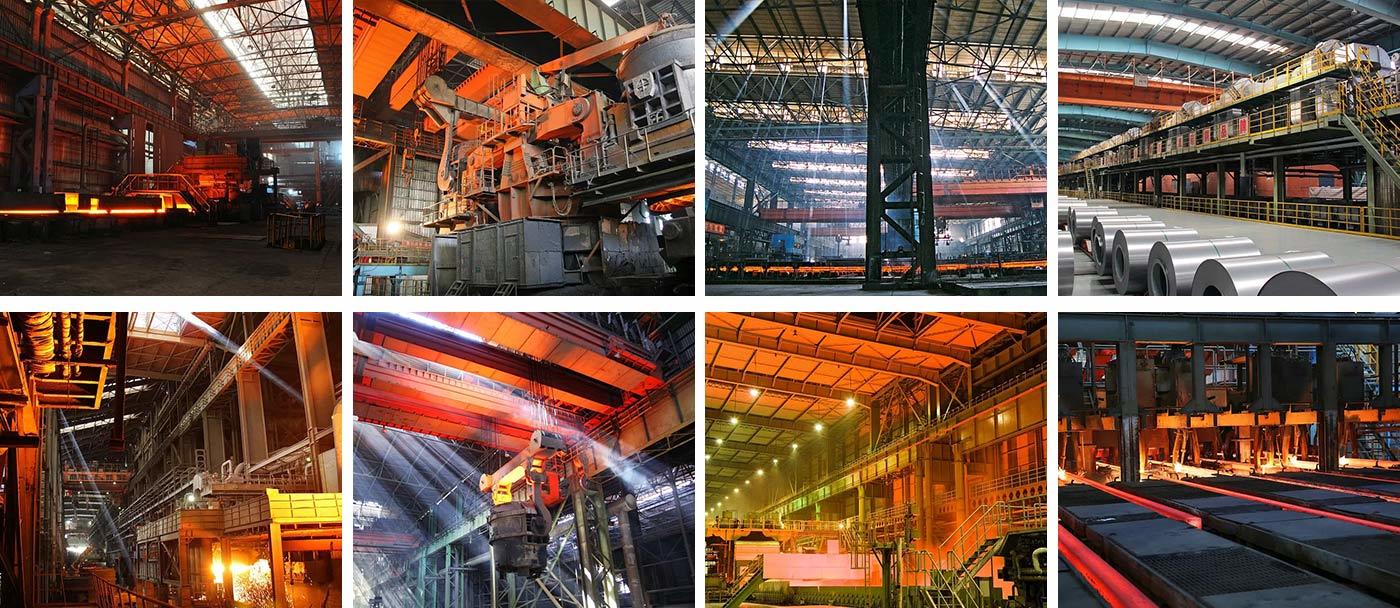

Warehouse storage

Shandong Jienuo Metal Products Co., Ltd. has a registered capital of 250 million yuan, more than 635 employees, 100 million yuan of property/plant equipment, covering an area of more than 300 acres, and has passed the international quality management system, energy management system, occupational health and safety management system and other standards. The company has advanced production equipment, superb technical force, excellent management and technical personnel, and strong financial strength to provide a strong guarantee for the production of high-quality, sophisticated and cutting-edge products.

Packing and delivery

The company has ISO9001 certification, EU CE10219 system certification, and Swiss SGS quality standard certification. In the future, the company will be a comprehensive modern enterprise featuring international trade and modern logistics as its development direction. Work together to make unremitting efforts for the green future of the steel industry in China and the world.

Application field

Widely used in prefabricated steel structure buildings, glass curtain wall engineering, steel structure engineering, large venues, airport construction, highways, roads, decorative guardrails, tower crane manufacturing, photovoltaic projects, greenhouse agricultural shanty buildings, bridge manufacturing, ships, automobile manufacturing, machinery In many fields such as manufacturing, it has been well received in major construction projects.

Cooperation transaction

Customer Visit Feedback

At the same time, we also look forward to sincere cooperation with customers and friends from all over the world, mutual benefit and win-win results, and common development, and create brilliant!

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

RELATED PRODUCTS

GET A FREE QUOTE